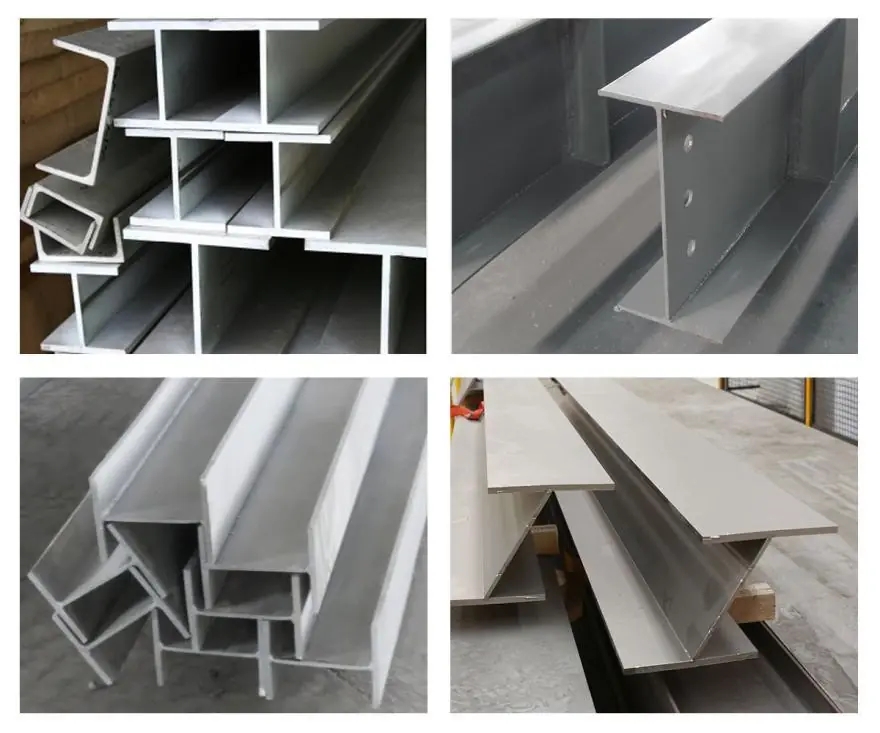

| Product Name | Inconel I Beam H Beam |

| Type | I Beam H Beam |

| Material | Nconel 718, Inconel 617,Inconel 601, Inconel 600, Inconel x-750, UNS N06601, UNS N06600,UNS N06625 |

| Thickness | 0.3-150mm |

| Length | 3000mm,5800mm,6000mm,9000mm,12000mm,etc. |

| Width | 40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Standard | ASTM,JIS, AISI, GB, DIN, EN |

| Surface | BA,2B,NO.1,NO.4,4K,HL,8K |

| Certification | ISO, SGS |

| Technique | Cold Rolled, Hot Rolled |

| Edge | Mill Edge Slit Edge |

| Quality | SGS Inspection |

| Price Term | CIF CFR FOB EX-WORK |

| Payment Terms | T/T L/C and Western Union etc |

| Application | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components. It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc. |

INGREDIENT:

| SEQUENCE | DIN/EN | UNS NO | GENERIC TERM | INGREDIENT |

| 1 | 2.4816 | N06600 | INCONEL Alloy 600 | 72Ni-151Cr-8Fr-0.2Cu-0.02C |

| 2 | 2.4851 | N06601 | INCONEL Alloy 601 | 60Ni-22Cr-1.2Al-0.02C |

| 3 | 2.4856 | N06625 | INCONEL Alloy 625 | 58Ni-21Cr-9Mo-3.5Nb-1CO-0.02C |

| 4 | 2.4856 | N06626 | INCONEL Alloy 625LCF | 58Ni-21Cr-9Mo-3.5Nb-1CO-0.02C |

| 5 | 2.4606 | N06686 | INCONEL Alloy 686 | 57Ni-21Cr-16Mo-4W-0.01C |

| 6 | 2.4642 | N06690 | INCONEL Alloy 690 | 58Ni-30Cr-9Fe-0.2Cu-0.02C |

| 7 | 2.4668 | N07718 | INCONEL Alloy 718 | 52Ni-19Cr-5Nb-3Mo-1Ti-0.6Al-0.02C |

| 8 | 2.4669 | N07750 | INCONEL Alloy 750 | 70Ni-15Cr-6Fe-2.5Ti-0.06Al-1Nb-0.02C |