The stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, and is resistant to corrosion by acids, alkaline gases, solutions and other media.

It is an alloy steel that does not rust easily, but not absolutely rust-free. Stainless steel plate refers to a steel plate that is resistant to corrosion by weak media such as atmosphere,

steam and water, while acid-resistant steel plate refers to a steel plate that is resistant to corrosion by chemically corrosive media such as acid, alkali, and salt. Stainless steel plate

has been around for more than a century since it came out at the beginning of the 20th century.

Stainless steel plate is generally a general term for stainless steel plate and acid-resistant steel plate. There are many types of stainless steel plate and steel plate with different

properties. It has gradually formed several categories in the development process.

According to the organizational structure, it is divided into four categories: austenitic stainless steel, martensitic stainless steel (including precipitation hardening stainless steel),

ferritic stainless steel, and austenitic plus ferrite duplex stainless steel.

Steel is an alloy of iron and carbon. Stainless steels are steels containing at least 10.5% chromium, less than 1.2% carbon and other alloying elements. Stainless steel’s corrosion resistance and

mechanical properties can be further enhanced by adding other elements, such as nickel, molybdenum, titanium, niobium, manganese, etc.

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

N |

Cu |

|

201 |

≤0.15 |

≤0.75 |

5.5~7.5 |

≤0.060 |

≤0.03 |

16.00~18.00 |

3.5~5.5 |

- |

- |

0.08 |

|

202 |

≤0.15 |

≤1.00 |

7.5~10.00 |

≤0.060 |

≤0.03 |

17.00~19.00 |

4.0~6.0 |

- |

≤0.25 |

|

|

301 |

≤0.15 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

16.00~18.00 |

6.00~8.00 |

- |

||

|

302 |

≤0.15 |

≤1.00 |

≤2.00 |

≤0.035 |

≤0.03 |

17.00~19.00 |

8.00~10.00 |

- |

||

|

304 |

≤0.07 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

18.00~20.00 |

8.00~10.50 |

- |

||

|

304L |

≤0.030 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

18.00~20.00 |

9.00~13.00 |

- |

||

|

310S |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

24.00~26.00 |

19.00~22.00 |

- |

||

|

316 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

16.00~18.00 |

10.00~14.00 |

2.00~3.00 |

||

|

316L |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

16.00~18.00 |

12.00~15.00 |

2.00~3.00 |

||

|

321 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

17.00~19.00 |

9.00~13.00 |

- |

||

|

430 |

≤0.12 |

≤0.75 |

≤1.00 |

≤0.040 |

≤0.03 |

16.00~18.00 |

- |

|||

|

2205 |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.030 |

≤0.015 |

22.00~23.00 |

4.5~6.5 |

2.5~3.5 |

||

|

2507 |

≤0.03 |

≤0.08 |

≤1.20 |

≤0.035 |

≤0.015 |

24.00~26.00 |

6.00~8.00 |

3.0~5.0 |

||

|

904L |

≤0.02 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.035 |

19.00~23.00 |

23.00~28.00 |

4.0~5.0 |

1.0~2.0 |

|

|

INCONEL 028 |

≤0.03 |

≤1.00 |

≤2.50 |

≤0.030 |

≤0.030 |

≤28.0 |

≤34.0 |

≤4.0 |

≤1.4 |

|

|

MONEL 400 |

≤0.30 |

≤0.5 |

≤2.00 |

- |

≤0.024 |

- |

≥63.0 |

- |

≤34.0 |

|

|

INCONEL 800 |

≤0.10 |

≤1.00 |

≤1.50 |

- |

≤0.015 |

≤23.0 |

≤35 |

4.0~5.0 |

- |

≤0.75 |

Standard Specification

| Thickness | 0.01mm-100mm | ||||||

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc | ||||||

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc | ||||||

| Surface | 2B, 2D, BA, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc | ||||||

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) | ||||||

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

||||||

|

Surface finish |

Thickness |

Size |

Characteristics |

Application |

|

NO. 1 |

3-100mm |

Width: 1500/1800/2000mm; |

Finished by hot-rolling, annealing and pickling, characterized by white pickled surface |

Chemical industry equipment, Industrial tanks |

|

2B |

0.2-6.0mm |

Width: 1000/1219/1500/1800/2000mm; |

Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface |

General Application Medical Instruments,Tableware |

|

No. BA |

0.2-3.0mm |

Width: 1000mm,1219mm; |

Bright heat treatment after cold rolling |

Kitchen utensil, kitchen ware,architectural purpose |

|

NO.4 Satin |

0.3-8.0mm |

Width: 1000/1219/1500mm; |

Polishing with No. 150 to No.320 mesh abrasivesThe most popular finishes |

Milk & Food processing acilities, Hospital Equipment, Bath-tub |

|

8K Mirror |

0.3-10mm |

Width: 1000/1219/1500mm; |

A mirror-like reflective surface by polishing with finer abrasives over 800 mesh |

Reflector, Mirror, Interior-Exterior decoration forbuilding |

|

HL(Hairline) |

0.3-8mm |

Width: 1000/1219/1500mm; |

Finished by continuous linear polishing |

Architectural purposes, escalators, kitchen ware vehicles |

FAQ:

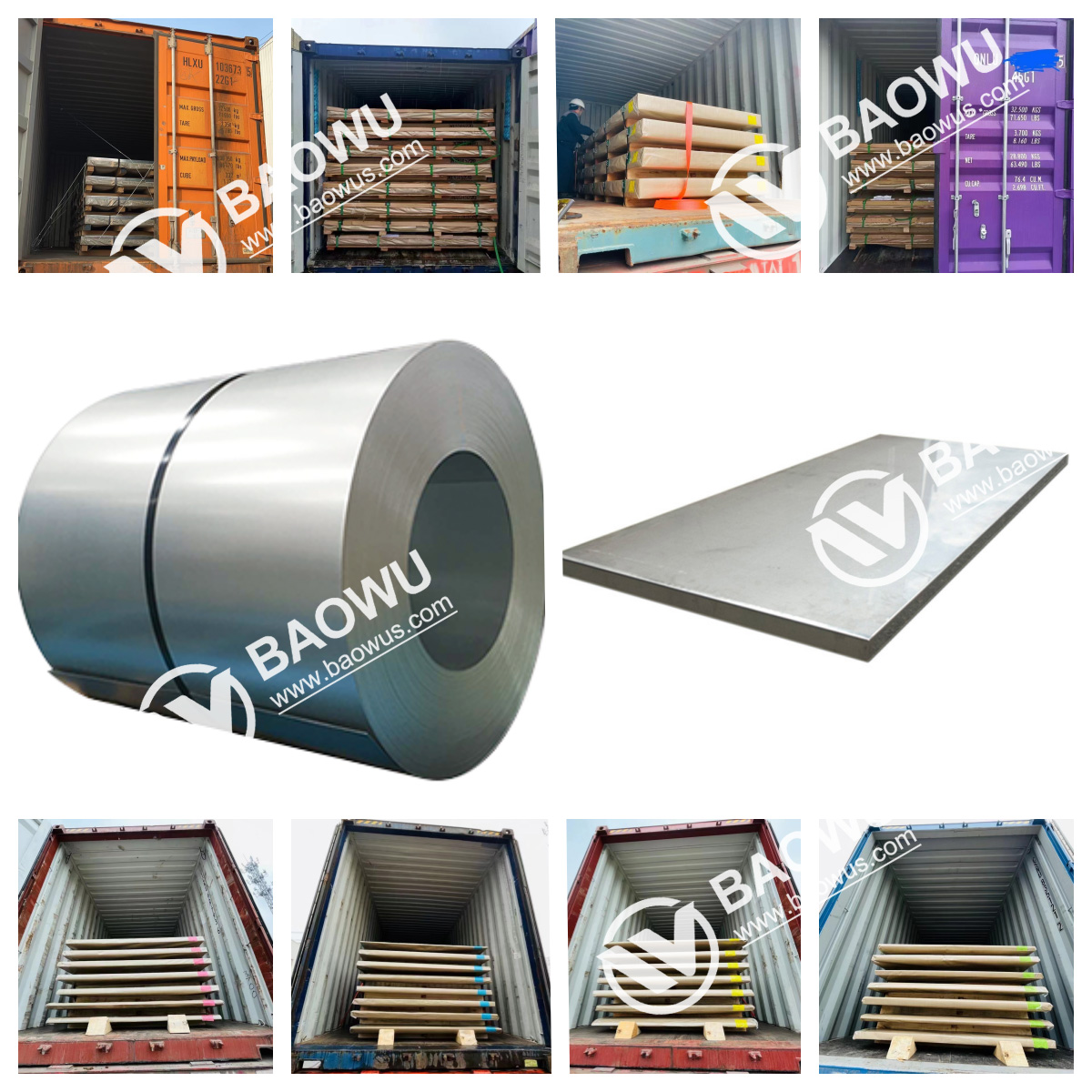

Q: What kind of work does your company do?

A: We are a business steel industry and trade. We mainly produces stainless steel plate/pipe/coil/round bars etc.

Q: What are the advantages of your company?

A: (1): Prime quality and Competitive price.

(2): Excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Samples can be provided as your requirements.

Q: What is your terms of payment ?

A: Can be negotiated by both parties. If you have another question, pls feel free to contact us as below

Q: What about your price?

A: Our price is very competitive.

Pls feel free to contact us if you are interested in our products.

Q: How long is your delivery time?

A: Stock steel/Steel for simple cutting/Small amount of general standard steel: about 5-20 days for delivery; Custom steel/bulk steel: about 15-30 days for delivery. Contact us for specific delivery times.