| Thickness | 0.3-100mm |

| Width | 600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Surface | BA/2B/NO.1/NO.4/8K/HL |

| Quality test | we can offer MTC(mill test certificate) |

| Payment terms | L/C T/T (30%DEPOSIT) |

| Stock or not | enough stock |

| Sample | Provided Freely |

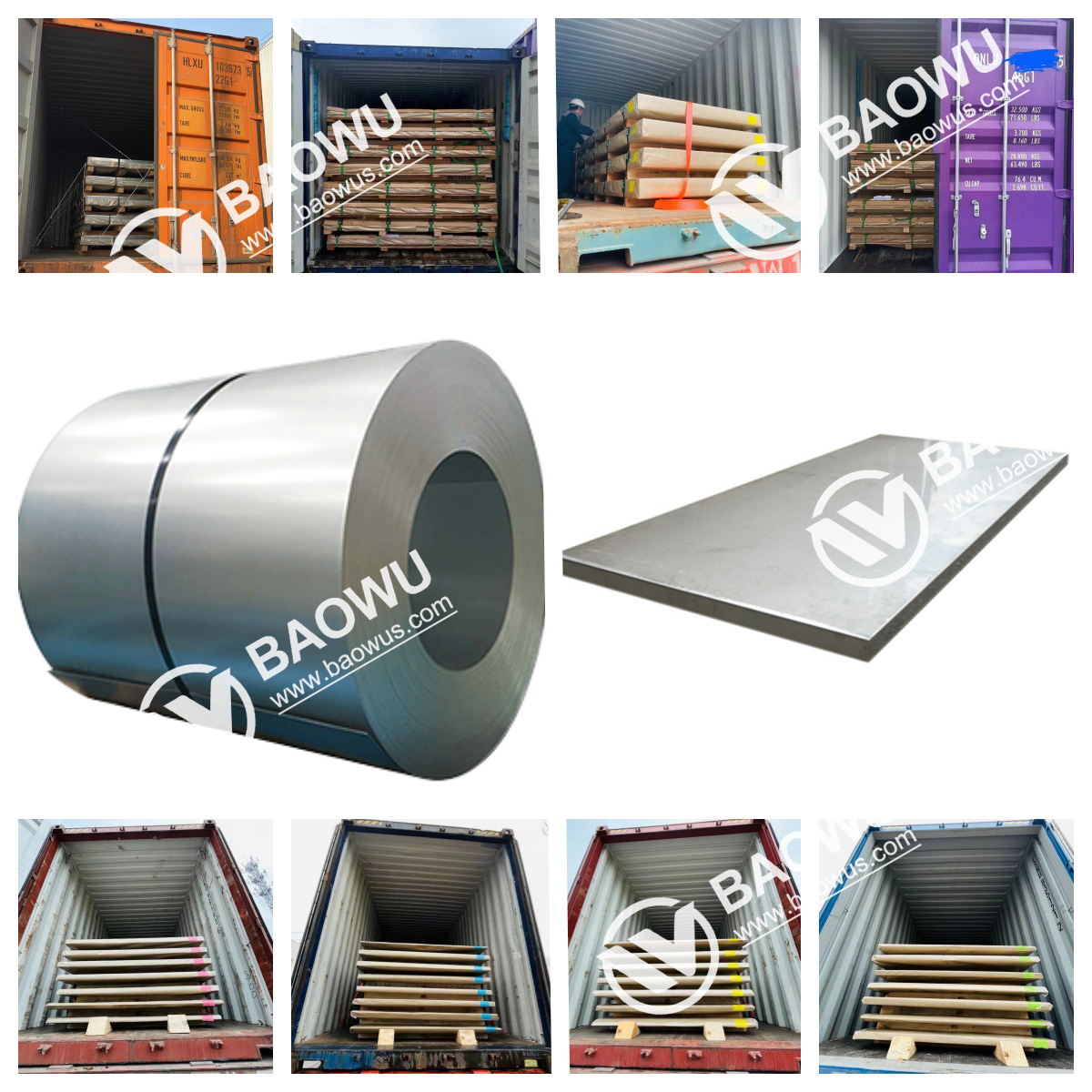

| Container Size | 20ft GP: 5898mm(Length)x2352mm(Width)x2393mm(High) 40ft GP: 12032mm(Length)x2352mm(Width)x2393mm(High) 40ft HC: 12032mm(Lengh)x2352mm(Width)x2698mm(High) |

| Delivery time | Within 7-10 Working Days |

Main features:

Weldability

Different product uses have different requirements for welding performance. A class of tableware generally does not require welding performance, and even includes some pot enterprises.

However, most products require good welding performance of raw materials, such as second-class tableware, thermos cups, steel pipes, water heaters, water dispensers, etc.

Corrosion resistance

Most stainless steel products require good corrosion resistance, such as first and second class tableware, kitchen utensils, water heaters, water dispensers, etc.When the amount of chromium

atoms in the steel is not less than 12.5%, the electrode potential of the steel can be abruptly changed from negative potential to positive electrode potential. Prevent electrochemical corrosion.

Polishing performance

In today's society, stainless steel products are generally polished during production, and only a few products such as water heaters and water dispenser liner do not need polishing. Therefore,

this requires that the polishing performance of the raw material is very good. The main factors that affect the polishing performance are as follows:

① surface defects of raw materials. Such as scratches, pitting, pickling, etc.

②The problem of raw materials. If the hardness is too low, it will not be easy to polish when polishing (the BQ property is not good), and if the hardness is too low, the orange peel phenomenon

is easy to appear on the surface during deep drawing, thus affecting the BQ property. BQ properties with high hardness are relatively good.

③ For the deep-drawn product, small black spots and RIDGING will appear on the surface of the area with a large amount of deformation, thus affecting the BQ performance.

Heat resistance

Heat resistance means that stainless steel can still maintain its excellent physical and mechanical properties at high temperatures.

Steel is an alloy of iron and carbon. Stainless steels are steels containing at least 10.5% chromium, less than 1.2% carbon and other alloying elements. Stainless steel’s corrosion resistance and

mechanical properties can be further enhanced by adding other elements, such as nickel, molybdenum, titanium, niobium, manganese, etc.

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

N |

Cu |

|

201 |

≤0.15 |

≤0.75 |

5.5~7.5 |

≤0.060 |

≤0.03 |

16.00~18.00 |

3.5~5.5 |

- |

- |

0.08 |

|

202 |

≤0.15 |

≤1.00 |

7.5~10.00 |

≤0.060 |

≤0.03 |

17.00~19.00 |

4.0~6.0 |

- |

≤0.25 |

|

|

301 |

≤0.15 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

16.00~18.00 |

6.00~8.00 |

- |

||

|

302 |

≤0.15 |

≤1.00 |

≤2.00 |

≤0.035 |

≤0.03 |

17.00~19.00 |

8.00~10.00 |

- |

||

|

304 |

≤0.07 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

18.00~20.00 |

8.00~10.50 |

- |

||

|

304L |

≤0.030 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

18.00~20.00 |

9.00~13.00 |

- |

||

|

310S |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

24.00~26.00 |

19.00~22.00 |

- |

||

|

316 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

16.00~18.00 |

10.00~14.00 |

2.00~3.00 |

||

|

316L |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

16.00~18.00 |

12.00~15.00 |

2.00~3.00 |

||

|

321 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

17.00~19.00 |

9.00~13.00 |

- |

||

|

430 |

≤0.12 |

≤0.75 |

≤1.00 |

≤0.040 |

≤0.03 |

16.00~18.00 |

- |

|||

|

2205 |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.030 |

≤0.015 |

22.00~23.00 |

4.5~6.5 |

2.5~3.5 |

||

|

2507 |

≤0.03 |

≤0.08 |

≤1.20 |

≤0.035 |

≤0.015 |

24.00~26.00 |

6.00~8.00 |

3.0~5.0 |

||

|

904L |

≤0.02 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.035 |

19.00~23.00 |

23.00~28.00 |

4.0~5.0 |

1.0~2.0 |

|

|

INCONEL 028 |

≤0.03 |

≤1.00 |

≤2.50 |

≤0.030 |

≤0.030 |

≤28.0 |

≤34.0 |

≤4.0 |

≤1.4 |

|

|

MONEL 400 |

≤0.30 |

≤0.5 |

≤2.00 |

- |

≤0.024 |

- |

≥63.0 |

- |

≤34.0 |

|

|

INCONEL 800 |

≤0.10 |

≤1.00 |

≤1.50 |

- |

≤0.015 |

≤23.0 |

≤35 |

4.0~5.0 |

- |

≤0.75 |

According to the definition in GB/T20878-2007, stainless steel is mainly characterized by stainless steel and corrosion resistance, and the chromium content is at least 10.5%, and the carbon

content is not more than 1.2%.

Stainless steel is the abbreviation of stainless and acid-resistant steel. The steel that is resistant to weak corrosive media such as air, steam, and water or has stainless steel is called stainless

steel. The steel grade is called acid-resistant steel.

Due to the difference in chemical composition of the two, their corrosion resistance is different. Ordinary stainless steel is generally not resistant to chemical medium corrosion, while

acid-resistant steel is generally stainless. The term "stainless steel" does not simply refer to one type of stainless steel, but to more than one hundred industrial stainless steels, each developed

to perform well in its specific field of application. The key to success is to first understand the application and then determine the correct steel grade. There are usually only six steel grades

associated with building construction applications. They all contain 17-22% chromium, and the better grades also contain nickel. The addition of molybdenum can further improve

atmospheric corrosion, especially corrosion resistance to chloride-containing atmospheres.

Generally speaking, the hardness of stainless steel is higher than that of aluminum alloy, and the cost of stainless steel is higher than that of aluminum alloy.

FAQ:

Q: What kind of work does your company do?

A: We are a business steel industry and trade. We mainly produces stainless steel plate/pipe/coil/round bars etc.

Q: What are the advantages of your company?

A: (1): Prime quality and Competitive price.

(2): Excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Samples can be provided as your requirements.

Q: What is your terms of payment ?

A: Can be negotiated by both parties. If you have another question, pls feel free to contact us as below

Q: What about your price?

A: Our price is very competitive.

Pls feel free to contact us if you are interested in our products.

Q: How long is your delivery time?

A: Stock steel/Steel for simple cutting/Small amount of general standard steel: about 5-20 days for delivery; Custom steel/bulk steel: about 15-30 days for delivery. Contact us for specific delivery times.